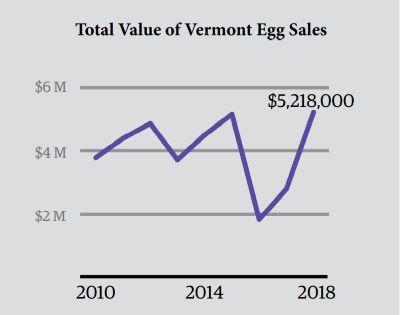

Farm-fresh eggs have long been an inexpensive source of high-quality protein and a popular choice for consumers looking to support local farms. Eggs have a relatively low cost of entry for diversified farmers looking to add a new small-scale enterprise. While demand is generally high, farmers have often found limited profitability due to lack of efficiency in production and high feed costs. As a result, many diversified farmers experiment with selling eggs for a period of time but not many have scaled up to a commercial level. Significant opportunity exists for Vermont farmers to expand their egg operations in a way that is complementary to their other products and markets.

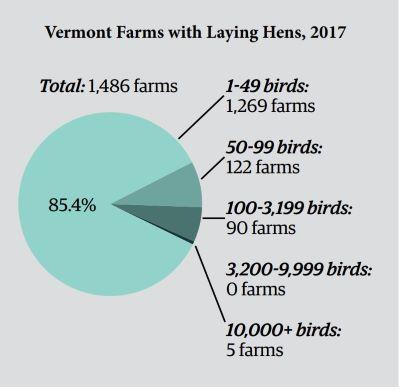

The commercial poultry industry has been largely concentrated in other parts of the country with low feed costs and proximity to processing facilities. (For meat poultry, see Poultry brief.) Eggs are mostly sold in Vermont as Grade A (i.e., fresh eggs) and must be labeled according to state regulatory requirements.1 Vermont egg producers are generally small-scale and sell directly to consumers through farm stands and farmers markets, and/or sell wholesale to small co-ops and retailers. A commercial-scale wholesale market for organic eggs is now available to large producers, selling to New Hampshire-based Pete and Gerry’s Eggs. Wholesale organic egg production to a large buyer like Pete and Gerry’s requires considerable investment in facilities and expertise and offers the potential for significant income, stable markets, and no time spent washing or marketing eggs.2 Very few Vermont egg producers have had success selling directly to regional grocery chains due to lack of scale, processing efficiency, and low wholesale prices.

There are significant gains in efficiency when scaling up poultry production, which has meant that commodity egg markets are dominated by very large producers that sell eggs at very low prices. Vermont farms will generally need to find high-value markets that reward production and marketing attributes such as organic, free-range, pastured, and local. Reducing feed costs and increasing efficiency are essential to building a profitable egg business. Mid-size farms with 300-3,000 hens generally can find good markets and may be profitable if they can keep production up and expenses down. Flocks over 3,000 birds fall under additional USDA and FDA regulations with specific sanitation and record-keeping requirements and inspections.